Well, we got a bit done on the ol' A7 today, finally got a welder to do what it says on the tin. Do reckon that MIG is a bit harsh for some of the work though, two minutes to lay the weld down and then two hours to file it and dress it. TIG gotta be the answer, but the cost seems pretty prohibitive at the moment.

Still, got the seat nose piece pivot all welded up and welded up the frame of the seat as well. This was done to get rid of the poorly applied rivets that come fitted.

Welded up the upper mudguard support brackets, that's quite pleasing as even without any rear support it seems pretty darn rigid and will self support quite happily.

Did a little welding on the rear numberplate support, this looks OK, but seeing as this will be a feature piece, the rest will now be TIG welded elsewhere.

Saturday 27 March 2010

Wednesday 24 March 2010

Cases came at last.

The XB32 cases arrived today. About a week late but pretty much as described. Being real early, they are what they call the thin flange type, this is the strengthening flange that runs around the mating face on the outside of the case. Apparently the later DBD 34 cases are nearer 1/2" here, whereas these are about 3/16". Ain't really worried as I don't intend to go racing.

I reckon it will be best to send 'em up to Phil Pearson before anything else, get 'em vapour blasted and inspected. Make sure we're building on reasonable foundations.

I reckon it will be best to send 'em up to Phil Pearson before anything else, get 'em vapour blasted and inspected. Make sure we're building on reasonable foundations.

Monday 22 March 2010

Maybe not all that was hoped for..........

Well, that was that then. Cliff's welder decided to not work again when we got it back, and Johnny's bargain is in danger of being surgically inserted back to the vendor. Should'a bought a new one to start with, easy to say now of course.

Went up to my ol' mate Geoff's yesterday, and saw this up for grabs

It's a 1949 500cc B33 motor slotted into an M20 frame. It's been brought in from India and by all accounts is a runner. It would make a great basis for the Single Project although the price is a little steep at the moment. Whilst we are actively seeking bits to stockpile for the next project, this is a little too much to lay out with the old A7 still needing cash spending on it.

Interesting to get the opportunity to study an original pair of BSA girders though. Didn't realise that the legs actually taper inwards between the top and bottom links. Also the rear legs are 7/8" (22 mm) diameter and the front 5/8" (16mm), strange how details elude until you start to look a bit closer. There are a few detail shots over on the girder page.

On a brighter note,

Went up to my ol' mate Geoff's yesterday, and saw this up for grabs

It's a 1949 500cc B33 motor slotted into an M20 frame. It's been brought in from India and by all accounts is a runner. It would make a great basis for the Single Project although the price is a little steep at the moment. Whilst we are actively seeking bits to stockpile for the next project, this is a little too much to lay out with the old A7 still needing cash spending on it.

Interesting to get the opportunity to study an original pair of BSA girders though. Didn't realise that the legs actually taper inwards between the top and bottom links. Also the rear legs are 7/8" (22 mm) diameter and the front 5/8" (16mm), strange how details elude until you start to look a bit closer. There are a few detail shots over on the girder page.

Friday 19 March 2010

Welding in a two up stylee

As mentioned before, we've been having trouble with the "new" welder, not feeding the wire at a constant rate. We got some 0.6mm now and that will be tried tomorrow, in the meantime Cliff at work has got a MIG welder that no longer arcs, so I asked him if we could borrow the feed wheel off of it, to see if it fits. "Tell ya what" he says "it ain't no good to me, you can have it, I'll bring it into work tomorrow and you can pick it up" Result thinks I, phone Johnny re: van availability, yep that's cool, so game on. Cliff then phoned me up at home and says that he's dragged it out, plugged it in to check it was feeding, and then struck the wire against the earth and whaddya know, it's spark city! So he tells me, that's OK pick it up anyway, and keep hold of it until the bikes finished. Quality or what? Welding frenzy!!!!!!!!!

Wednesday 17 March 2010

More decisions

One of the things that keeps croppin' up is what to do with the motor. When the bike was first put together in the late '70s, Crinkle Black crank cases and chromed outer cases was cool and groovy, and all credit to the chrome platers of the day, the vast majority of it has lasted very well. One thought was to leave the plating on the covers and to the main cases gloss black, as seen on Vincents, the black not the chrome. Would certainly look nice and be pretty unusual on an old Brit nowadays, but there's always the chance that it would look anachronistic when the bike is fully finished as bright plating elsewhere is being kept to a minimum.

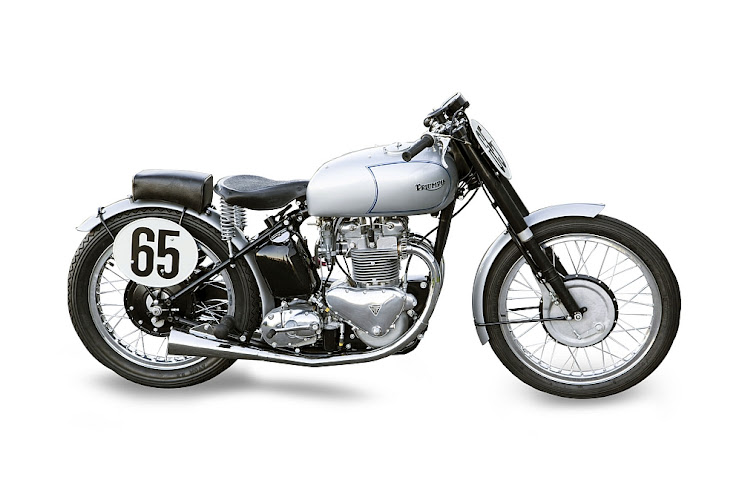

Then today on http://www.stevestockers.blogspot.com/ these pictures were posted,

It's difficult to imagine any red blooded male not getting excited about these pictures. Bearing in mind, the long stroke A7 has cast iron head and barrels, it would not look this stunning, but maybe gloss black on those parts and a vapour blast on the crank cases with polished outers may well do the trick. Can't wait to see the finished bike that this is going into.

It's difficult to imagine any red blooded male not getting excited about these pictures. Bearing in mind, the long stroke A7 has cast iron head and barrels, it would not look this stunning, but maybe gloss black on those parts and a vapour blast on the crank cases with polished outers may well do the trick. Can't wait to see the finished bike that this is going into.

Sunday 14 March 2010

Number Plate Bracket Get's Started

Having got all the bits together, work could start on the number plate and mounting set-up. The idea is to use the existing cast lugs on the frame, originally intended as sidecar mounts. These are quite a large casting, some 38mm OD and 32mm ID, so it meant a large sleeve to accommodate it. The picture below shows the upright in position, loosely attached to the sleeve.

The large bolt head in the center is only there to keep it all in position, the rear light will be mounted through the sidecar lug as well. The upright had not been cut to final length at this stage and is still some 50mm too long.

This picture shows the support from the rear, and gives a better idea of how the sleeve encompasses the sidecar lug. It also shows a better view of the lower collar on the support pillar, the numberplate bracket is inserted into the slot that can be seen on the right hand side.

These are the parts that go together to build up the numberplate holder. The Lucas TR4 illumination lamp can be seen at the top along with the chrome surround. The bracket is also shown with the aluminium cover plate at the bottom.

This assembly of parts can be bought from this site, as a show plate only item.

The two pictures above show the TR4 light unit in position, it's easy to see why the finished result gives us so much pleasure 'round here. As stated previously, this was the vision, how it was hoped it would turn out, and voila, that's what we got.

And here it all is assembled, in this picture the cover plate is shown on the front to demonstrate it as a complete assembly if it is sold. The next picture shows the unit "roughed up" in position as can be seen by the insulating tape precariously holding it together. The upright has been cut down to what is, or very close to, the final height. Unfortunately there are still some issues with the "new" welder, and it was not possible to tack it up at this stage.

Just a final picture of the complete assembly viewed edge on to show how thin and compact it all is. We're very pleased with the outcome so far, although this shot does show how out of line it is at the moment.

There's still some way to go before it is finished, the final welding and an anti-rotation device to stop the whole lot turning round in use.

The large bolt head in the center is only there to keep it all in position, the rear light will be mounted through the sidecar lug as well. The upright had not been cut to final length at this stage and is still some 50mm too long.

This picture shows the support from the rear, and gives a better idea of how the sleeve encompasses the sidecar lug. It also shows a better view of the lower collar on the support pillar, the numberplate bracket is inserted into the slot that can be seen on the right hand side.

These are the parts that go together to build up the numberplate holder. The Lucas TR4 illumination lamp can be seen at the top along with the chrome surround. The bracket is also shown with the aluminium cover plate at the bottom.

This assembly of parts can be bought from this site, as a show plate only item.

The two pictures above show the TR4 light unit in position, it's easy to see why the finished result gives us so much pleasure 'round here. As stated previously, this was the vision, how it was hoped it would turn out, and voila, that's what we got.

And here it all is assembled, in this picture the cover plate is shown on the front to demonstrate it as a complete assembly if it is sold. The next picture shows the unit "roughed up" in position as can be seen by the insulating tape precariously holding it together. The upright has been cut down to what is, or very close to, the final height. Unfortunately there are still some issues with the "new" welder, and it was not possible to tack it up at this stage.

Just a final picture of the complete assembly viewed edge on to show how thin and compact it all is. We're very pleased with the outcome so far, although this shot does show how out of line it is at the moment.

There's still some way to go before it is finished, the final welding and an anti-rotation device to stop the whole lot turning round in use.

Thursday 11 March 2010

Looks like a good weekend looming

As promised, the number plate brackets have been made, the TR4 plate illumination lamp looks the mutts nutts when fitted. The mounting bar arrangement has been roughed out, it just needs sorting out for height and welding. As the rear of the pressed number plate shows the registration in mirror format, another alloy plate has been made to cover the back, there are plans afoot for this. Should have pix of it in an early style on the next post.

Johnny bought a MIG welder last weekend, and now he's scored some wire and gas to run on it. Assuming that it works as intended, may well get some progress sorted.

Been giving the girder project lot's of thought, especially on how to fabricate the yokes. It's only conceptualising at the moment as offset has to be calculated, I am guessing that the stem center and the pivot axis should be offset around 60mm if 100mm links are used.

Johnny bought a MIG welder last weekend, and now he's scored some wire and gas to run on it. Assuming that it works as intended, may well get some progress sorted.

Been giving the girder project lot's of thought, especially on how to fabricate the yokes. It's only conceptualising at the moment as offset has to be calculated, I am guessing that the stem center and the pivot axis should be offset around 60mm if 100mm links are used.

Wednesday 10 March 2010

Getting a few figures in place

The above drawing shows the early B31/B33 rigid frame, this frame and the dimensions shown will be used to calculate the lengths and geometry to build the girder fork.

The first dimension of note is the steering neck angle at 27 degrees from the vertical. A neck height can be closely approximated from the figures given, from the front tank mount to the upper front engine mount is 15 3/32", between the mounts is 5 29/32" and from the lower engine mount to the centre line of the lower chain stay is 1 1/2". Don't you just miss the old imperial measuring system? Those added together are 22 1/2" plus another 1/2" for the added thickness of the chain stay gives 23 and scaling the drawing visually there's probably another 2 inches to be added to allow for the rest of the neck height, leaving us with a total of 25". The one measurement that has not been factored in, is ground clearance.

Once again the drawing helps, it shows that the distance between the centre of the rear wheel spindle and the centre line of the lower chain stay is 6" plus the extra 1/2" for the lower half of the tube. So 6 1/2", or approximately 164 mm in new money, a 19" wheel rim with a 3.60 wide tyre measures 324 mm from the spindle centre vertically to the floor. 324 minus 164 is 160, so that will be the ground clearance with the lower rails parallel to the ground. Add this to our 633 mm (25") first figure and we end up with 793 mm. From this needs to be subtracted the wheel/tyre radius of 324 mm, leaving 469 mm vertical height. Armed with this figure and knowing the neck height we slip away to Engineers Edge and let the computer do the figuring, never can remember much Trig from school. The returned figures give a fork length of 536.25 mm and an initial trail of 260mm, these are now working measurements........... to be continued

Tuesday 9 March 2010

Mental ruminations

Picture sourced from www.hubpages.com

With the new found access to laser cutting I've been racking the ol' grey matter to try and come up with an application to exploit the possibilities. I am thinking now about making a set of girders, possibly for the A7, maybe the Chicaralike project.

There's certainly a hell of a lot to consider with regards geometry, materials and strength.

I am looking to build something around 24" in total length, probably out of 16mm (5/8")tube with a single spring/shock unit.

There are a few dimensions that do seem to be pretty much set in stone when it comes to front end design. Consensus seems to have it, that a road bike needs between 110 and 140 mm of trail to be stable and usable. The shorter the trail the "quicker" and more responsive the steering is, at the cost of straight line stability. At the moment this is an academic exercise and a working dimension of 125mm has been chosen. Another critical dimension seems to be the length of the active links, again much wiser people than yours truly seem to feel a length of 100 to 110 mm is the optimum. Also to maintain a smooth and even action through the arc of movement all four links must be exactly equal in length. A look at the picture above shows that uneven lengths top and bottom would cause the wheel spindle to prescribe an almost circular path as the suspension moved through it's stroke. Least ways, I think it would.

There's certainly some thinking to do here, but I find it pleasurable to have something to work through in my mind during those quiet moments........... to be continued

Back number plate bracket drawing was taken 'round the corner today for cutting, hope to see the results tomorrow.

Thursday 4 March 2010

A bit of a conundrum.......

Been getting a bit of a stirring in the nether regions this week regarding the potential offered by laser cutting. Basically the plot is, if it can be imagined and drawn in two dimensions on CAD then it can be turned into metal. For all intents and purposes, a laser cutter is a plotter with a cutting tip instead of a pen.

(Scanned picture, please excuse the wobbly appearance.)

This is the foundations of the back number plate bracket that was knocked up in about 20 minutes at lunchtime. There's still aways to go yet, but matey 'round the corner could and would cut it out of mild or stainless in no time flat.

So I showed a bloke at work who's got a Harley where I am going with the bracket, and he says "Yeah it's alright, but it ain't engineering is it ?. It's a machine doing the work"

That kinda threw me for a while, is he right? Then I started to think, if I'd have sketched the piece up, marked out a piece of plate and chain drilled it, then finished it of with a file I would have been made up to end up with the same piece. But then chain drill with an electric dill or with one of those hand drills with the handle on the side. Or one of them bow type devices that David Attenborough waxes lyrically about when native type blokes in the jungle make things? Just how far back do you go for authenticity?

So I decided, if the technology is available, have some of it! I went back round and told him Bollocks

(Scanned picture, please excuse the wobbly appearance.)

This is the foundations of the back number plate bracket that was knocked up in about 20 minutes at lunchtime. There's still aways to go yet, but matey 'round the corner could and would cut it out of mild or stainless in no time flat.

So I showed a bloke at work who's got a Harley where I am going with the bracket, and he says "Yeah it's alright, but it ain't engineering is it ?. It's a machine doing the work"

That kinda threw me for a while, is he right? Then I started to think, if I'd have sketched the piece up, marked out a piece of plate and chain drilled it, then finished it of with a file I would have been made up to end up with the same piece. But then chain drill with an electric dill or with one of those hand drills with the handle on the side. Or one of them bow type devices that David Attenborough waxes lyrically about when native type blokes in the jungle make things? Just how far back do you go for authenticity?

So I decided, if the technology is available, have some of it! I went back round and told him Bollocks

Tuesday 2 March 2010

More bits coming together.

The number plate lamp arrived today, nice I like it lots. It's genuine Lucas and was fitted to Triumph TR4 sports cars back in the day. I couldn't remember how big they were, just that they were pretty funky looking. The bloke who put it on the old auction site didn't use a ruler or anything to reference against. When the bag arrived I was a little disconcerted because the Lucas box was larger than I hoped, but when opened it was mostly full of wire, the light unit is only about an inch in diameter.

Got a load of mudguard brackets laser cut today, more as a test run to see how it worked. Good result as it turns out, took the drawing to the bloke at one o'clock, he's phoning me by four to say they're done. Told me that he was up for any more work in a similar stylee, nice bloke, nice work, job's a goodun.

Anybody want a pair then let me know, special discount if bought through this site.

Got a load of mudguard brackets laser cut today, more as a test run to see how it worked. Good result as it turns out, took the drawing to the bloke at one o'clock, he's phoning me by four to say they're done. Told me that he was up for any more work in a similar stylee, nice bloke, nice work, job's a goodun.

Anybody want a pair then let me know, special discount if bought through this site.

Subscribe to:

Posts (Atom)

.jpg)

-25.jpg)

.jpg)